Company:

The limited liability company Metalfil, s.r.o., has been founded in 1998, leveraging long-time experiences of its business partner in production of stands, with whom we work together in completion of products as well as finishing and special deliveries.

The company has also technology and design office using AutoCAD software for developing own projects or projects in cooperation with customers. Focus on project activity, organization and control of production cycle under direction of technicians with college and secondary education and specialized personnel guarantees high-quality standard of products and prompt delivery of orders for competitive prices. The company has also wide variety of machines and equipment enabling own production in major part of the production cycle.

- shop for own production of templates, models and manufacturing special equipment,

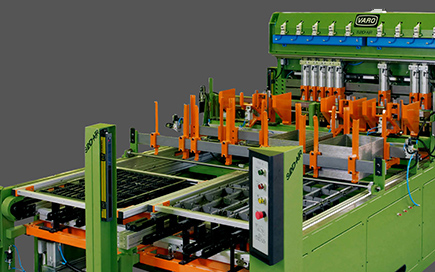

- shop for processing wires equipped with spot-welders of various types and output, 3D wire benders with separate welding working-site, separate robotized working-site performing automated spot welding and assembly, semi-automatic wire benders, vertical hydraulic benders, benders with material separation, grinding and trimming machines etc.

- unit of steel and wooden constructions equipped with laser for sheet metal cutting, MIG/MAG welding robot at separate working-site, bender of steel pipes and sections, various systems for cutting and rabbeting rounded or angular pipes etc., drilling and milling machines, MIG/MAG and TIG welding tables operated by personnel with welding certificate, unit of painting with automatic device for powder painting,

- unit of products completion, finishing, packing and dispatching.

- cooperating wood-processing shop located in the company premises,

- cooperation with two partner companies engaging in technical assembly in the company premises.

.png)